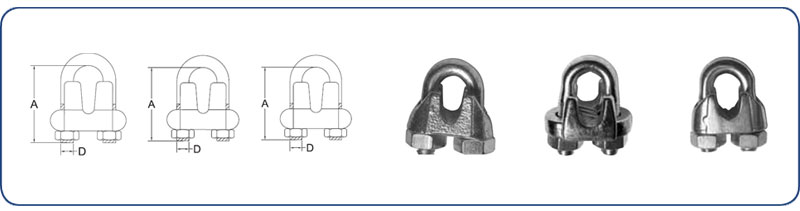

wire rope Clips

Our engineers work with you to provide the optimal product of the highest quality for orders of every size. Whether you need standard or a special cable assembly, we can assist you from inception to completion. Let our Sales Team help you out today.